Platonic Volumes and Cosmologies

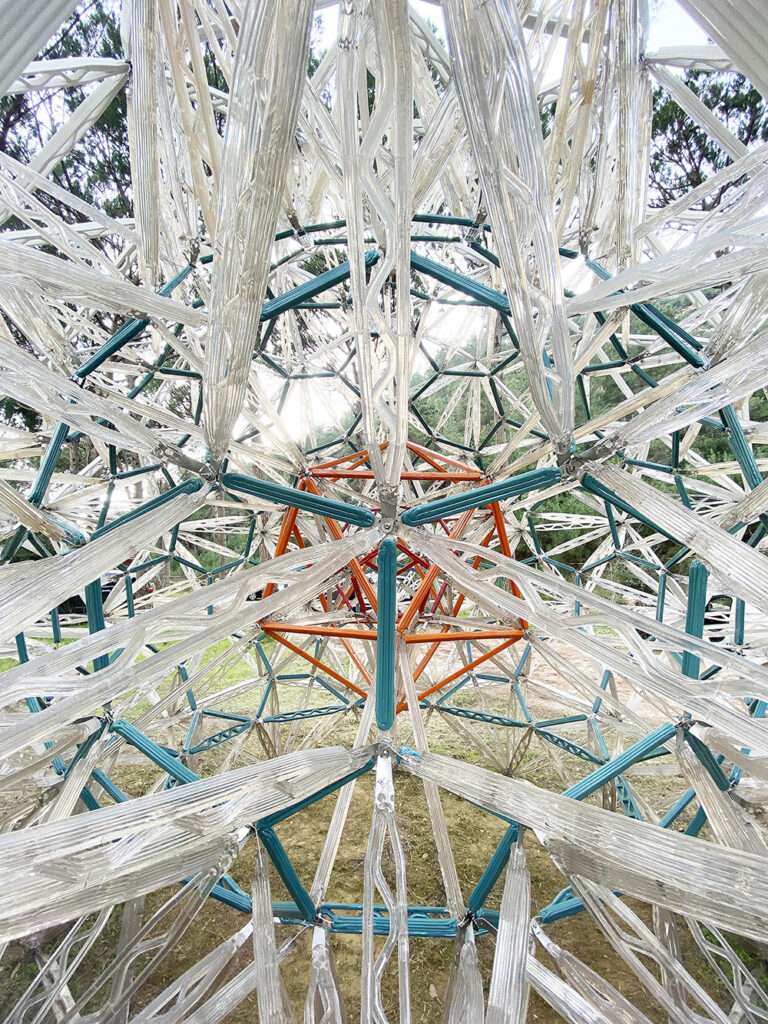

Platonic Volumes and Cosmologies is a large-scale lattice structure of inscribed platonic volumes illustrating a tipping point in scientific thinking derived from Kepler’s theories on cosmology.

Location: Brisbane, Australia

Year: 2021

Size: Height: 5m | Diameter: 5.5m

Program: Public Installation

Curiocity Brisbane is a 17-day celebration of science, art & tech, where new possibilities play and big ideas collide. It took place from 12 to 28 March 2021, with a program of interactive installations and events including World Science Festival Brisbane.

Platonic Volumes and Cosmologies:

an intriguing and inviting installation to discover the birth of scientific thinking

The installation/pavilion takes inspiration from Buckminster Fuller’s geodesic dome as well as Kepler’s cosmology hypothesis, in which the five Platonic solids represent the structure of the universe. The geosphere embraces the platonic solids volume after volume, each represented by a different colour. They are inscribed and connected within each other through transparent connections. Identifying and distinguishing the different volumes is part of the interaction with the pavilion itself. The pavilion is not only a visual exploration, but also a climbable physical experience.

Fabrication & process

While Bits to Atoms honoured the history of scientific thinking in the concept, the office implemented Curiocity’s theme, celebrating STEAM, in its fabrication of this pavilion. Bits to Atoms and Post Industrial Crafts used technological advancement, constant research on materials, and sustainable techniques to create innovative objects. By testing the limits of recycled polycarbonate, Post Industrial Crafts created a new type of structural elements. The beams that make up the “Platonic Volumes and Cosmologies” pavilion are entirely built from recycled plastic.

The innovative process uses a large 2.5 tons robotic arm, reclaimed from the automotive industry. Recycled, UV resistant, crushed polycarbonate is placed inside a hopper. The robotic arm moves the plastic extruder in space, laying a line of molten plastic. Stainless steel flanges are placed during the 3D printing while the plastic is still flowing, producing a high cohesion between the two materials. The geodesic geometry, combined with the high end polycarbonate material produce a very sturdy, climbable, and shockproof self- regulating structure. This patent pending innovative process paves the way for further experimentation with reusing recycled plastic as a structural element. Making way to further sustainable and waste-free design.